High Precision Deep Hole Processing of Titanium Alloy-Implementing High Efficiency Production of Helicopter Moving Parts

Helicopters are aircraft that rely entirely on huge rotors to provide lift and control. The manufacture of moving parts based on the hub is called "the pearl of the crown of helicopter manufacturing". In order to overcome this problem, solve the bottleneck of moving parts processing and increase production capacity, Kangding Metal took the ride of “Made in China 2025”. Modern CNC machining centers, composite material production lines and modern helicopter production lines have been built, which will contribute to the development of China's helicopter industry.

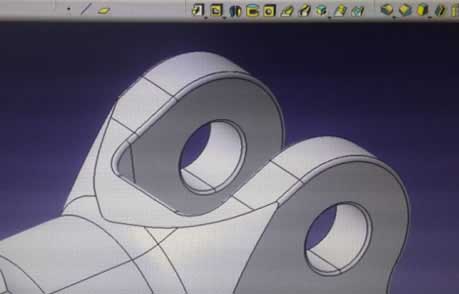

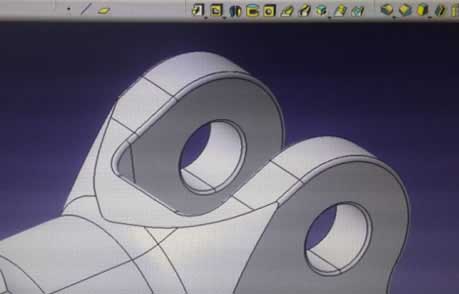

The moving parts of the helicopter need to bear the centrifugal force, the steering force and various alternating moments generated by the rotation of the blades, and they need excellent rigidity and good assembly dynamic balance. Therefore, as a hole system for connecting the moving parts, it is necessary to ensure extremely high aperture precision (H7 and above), good surface roughness (titanium alloy generally needs to reach Ra1.6), and relatively high positional accuracy. (see picture 1). Therefore, the finishing of the hole system is generally used as the last step of the machining of the moving parts, and is performed by a precision machine tool with a high-performance tool.

Figure 1 Rigorous aperture and surface roughness should be guaranteed in processing precision holes of helicopter moving parts

Efficient tooling solutions for superior quality

Limited to titanium alloy materials, precision holes for moving parts cannot be ground. Boring reaming is a common processing method in hole processing. Kangding also uses a large number of boring processing in the processing of precision holes of moving parts. Under the existing production conditions, Kangding has summed up a set of titanium alloy finishing tool solutions through continuous practice, which has realized the efficient production of helicopter maneuvering parts.

Boring cutter is an indispensable tool in precision hole processing. Precision boring can achieve high dimensional accuracy and good surface roughness. Boring reaming is a common processing method in hole processing. Kangding also uses a large number of boring processing in the processing of precision holes of moving parts. At present, the mainstream boring head uses the principle of screw to adjust the tool diameter, and the structure is much the same, so the positioning accuracy of the boring head in the process of processing is very important. After many practices, Kangding finally chose the A76002 boring head of Shangao brand. Its fine-tuning accuracy (in the direction of diameter) can reach 2.5 m, and its high diameter accuracy can achieve IT5. It is a highly rigid tool for the overall control of the geometry and surface roughness of the hole (up to Ra 0.6). To ensure the rigidity of the tool, the A76002 uses a “cylinder and flange” tool clamping design for higher speeds, higher productivity, higher precision and better surface finish. The precision-balanced A76002 allows for higher speeds, improved hole geometry and reduced machine tool spindle stress.

figure 2 A76002 Boring Head with Boring Bar has a 2-20mm Boring Cover and a larger dial.

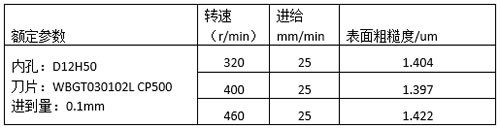

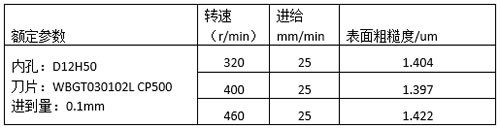

The choice of insert has a direct impact on the machining of titanium alloy holes. Excellent boring inserts maintain good surface roughness and roundness over a wide range of cutting parameters and effectively reduce the knives caused by deep hole boring. To this end, Kang Ding in the trial cutting process for the blade fillet, coating and different chipbreaker comparison test, combined with the operator's experience, selected several blades for process optimization (see Table 1). Among them, the CP500 with PVD coating has the toughness in stainless steel finishing and semi-finishing.

Boring parameters (FS value).

Titanium alloy has poor thermal conductivity and the material is sticky. Therefore, the cutting speed of the boring can not reach the material of steel or aluminum alloy, generally maintained at 30-35m/min to ensure the surface roughness is above Ra1.6. The Seco blades used in the test showed good processing accuracy on the test pieces. The coated CP500 series inserts offer better wear resistance and longevity, while the traditional 26G6 uncoated inserts are more economical. Table 2 shows the test results for the CP500 blade.

Determination of feed rate

A suitable amount of feed can be used to machine parts in place faster. In the processing of small diameter and large length-diameter ratio precision holes, it is necessary to pay attention to the occurrence of tool let-off phenomenon, and find out the rules of tool deformation and surface roughness shaping on the premise of stabilizing boring parameters. Taking a type of connector as an example, the double-pronged ear hole (see Figure 3) requires two holes with a diameter of Φ18+0.021 and a coaxiality of 0.05mm. A boring tool with a suspension length of at least 92 mm is required to complete the boring process once. A76002 hoe (see Figure 4) with a 95mm cemented carbide mast. Under the premise of rough to one side of about 0.2mm, the knife is fed according to 0.1mm, so that the amount of the knife is stable between 0.002 and 0.004. According to this rule, the operator can process the connecting hole in place after 3 - 4 feeds, and ensure the requirements of aperture and surface roughness.

image 3 Titanium alloy double fork ear hole processing

The processing of large diameter connecting holes of titanium alloy requires relatively slower speed and feeding, and finish with R0.4 blade. Figure 5 shows: The blade is matched with the Φ48+0.027, the coaxiality is 0.1mm, the space is 182mm, and the 46-50mm boring tool can still be processed in place after 3 times of feeding. If you use three boring tools to process in a fixed manner, the efficiency is higher.

Fig. 5 Titanium Alloy Connecting Hole Model

The moving parts of the helicopter need to bear the centrifugal force, the steering force and various alternating moments generated by the rotation of the blades, and they need excellent rigidity and good assembly dynamic balance. Therefore, as a hole system for connecting the moving parts, it is necessary to ensure extremely high aperture precision (H7 and above), good surface roughness (titanium alloy generally needs to reach Ra1.6), and relatively high positional accuracy. (see picture 1). Therefore, the finishing of the hole system is generally used as the last step of the machining of the moving parts, and is performed by a precision machine tool with a high-performance tool.

Figure 1 Rigorous aperture and surface roughness should be guaranteed in processing precision holes of helicopter moving parts

Efficient tooling solutions for superior quality

Limited to titanium alloy materials, precision holes for moving parts cannot be ground. Boring reaming is a common processing method in hole processing. Kangding also uses a large number of boring processing in the processing of precision holes of moving parts. Under the existing production conditions, Kangding has summed up a set of titanium alloy finishing tool solutions through continuous practice, which has realized the efficient production of helicopter maneuvering parts.

Boring cutter is an indispensable tool in precision hole processing. Precision boring can achieve high dimensional accuracy and good surface roughness. Boring reaming is a common processing method in hole processing. Kangding also uses a large number of boring processing in the processing of precision holes of moving parts. At present, the mainstream boring head uses the principle of screw to adjust the tool diameter, and the structure is much the same, so the positioning accuracy of the boring head in the process of processing is very important. After many practices, Kangding finally chose the A76002 boring head of Shangao brand. Its fine-tuning accuracy (in the direction of diameter) can reach 2.5 m, and its high diameter accuracy can achieve IT5. It is a highly rigid tool for the overall control of the geometry and surface roughness of the hole (up to Ra 0.6). To ensure the rigidity of the tool, the A76002 uses a “cylinder and flange” tool clamping design for higher speeds, higher productivity, higher precision and better surface finish. The precision-balanced A76002 allows for higher speeds, improved hole geometry and reduced machine tool spindle stress.

figure 2 A76002 Boring Head with Boring Bar has a 2-20mm Boring Cover and a larger dial.

The choice of insert has a direct impact on the machining of titanium alloy holes. Excellent boring inserts maintain good surface roughness and roundness over a wide range of cutting parameters and effectively reduce the knives caused by deep hole boring. To this end, Kang Ding in the trial cutting process for the blade fillet, coating and different chipbreaker comparison test, combined with the operator's experience, selected several blades for process optimization (see Table 1). Among them, the CP500 with PVD coating has the toughness in stainless steel finishing and semi-finishing.

Boring parameters (FS value).

Titanium alloy has poor thermal conductivity and the material is sticky. Therefore, the cutting speed of the boring can not reach the material of steel or aluminum alloy, generally maintained at 30-35m/min to ensure the surface roughness is above Ra1.6. The Seco blades used in the test showed good processing accuracy on the test pieces. The coated CP500 series inserts offer better wear resistance and longevity, while the traditional 26G6 uncoated inserts are more economical. Table 2 shows the test results for the CP500 blade.

Determination of feed rate

A suitable amount of feed can be used to machine parts in place faster. In the processing of small diameter and large length-diameter ratio precision holes, it is necessary to pay attention to the occurrence of tool let-off phenomenon, and find out the rules of tool deformation and surface roughness shaping on the premise of stabilizing boring parameters. Taking a type of connector as an example, the double-pronged ear hole (see Figure 3) requires two holes with a diameter of Φ18+0.021 and a coaxiality of 0.05mm. A boring tool with a suspension length of at least 92 mm is required to complete the boring process once. A76002 hoe (see Figure 4) with a 95mm cemented carbide mast. Under the premise of rough to one side of about 0.2mm, the knife is fed according to 0.1mm, so that the amount of the knife is stable between 0.002 and 0.004. According to this rule, the operator can process the connecting hole in place after 3 - 4 feeds, and ensure the requirements of aperture and surface roughness.

image 3 Titanium alloy double fork ear hole processing

The processing of large diameter connecting holes of titanium alloy requires relatively slower speed and feeding, and finish with R0.4 blade. Figure 5 shows: The blade is matched with the Φ48+0.027, the coaxiality is 0.1mm, the space is 182mm, and the 46-50mm boring tool can still be processed in place after 3 times of feeding. If you use three boring tools to process in a fixed manner, the efficiency is higher.

Fig. 5 Titanium Alloy Connecting Hole Model